Whatsminer M34S+ Water Cooling Miner Repair Manual

I. Requirements for the repair environment, tools, and equipment

1. Testing program: Mobxterm

2. Test command:

Hash board testing | ft-readchipid |

Power on | echo 1>/sys/class/gpio/gpio356/value |

When the test line is connected to ports 0 and 1 of the control board: | |

RST set to 1.8V | echo 1>/sys/class/gpio/gpio197/value |

RST set to 0v | Echo 0>/sys/class/gpio/gpio197/value |

When connecting the test leads to terminals 2 and 3 of the control board: | |

RST set to 1.8V | echo 1>/sys/class/gpio/gpio202/value |

RST set to 0v | Echo 0>/sys/class/gpio/gpio202/value |

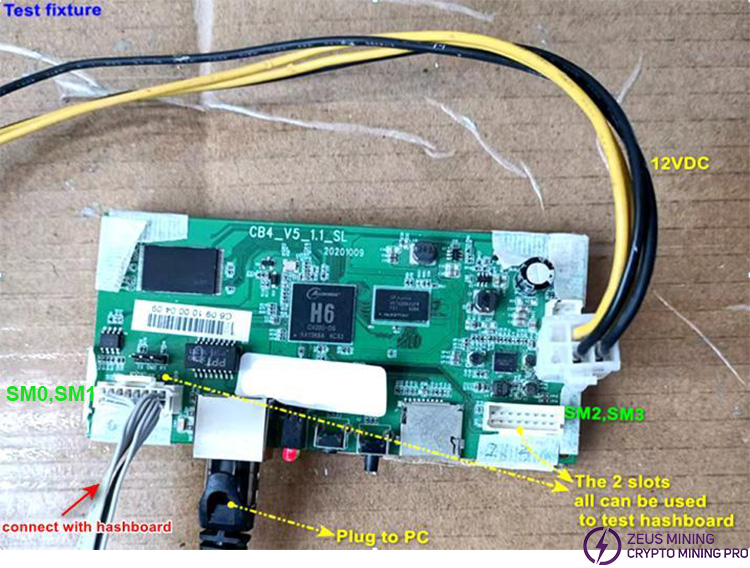

3. Test fixture control board: Water cooling miner control board (CB4/CB5/CB6)

4. Test cable: The communication signal cable that comes with the water cooling miner

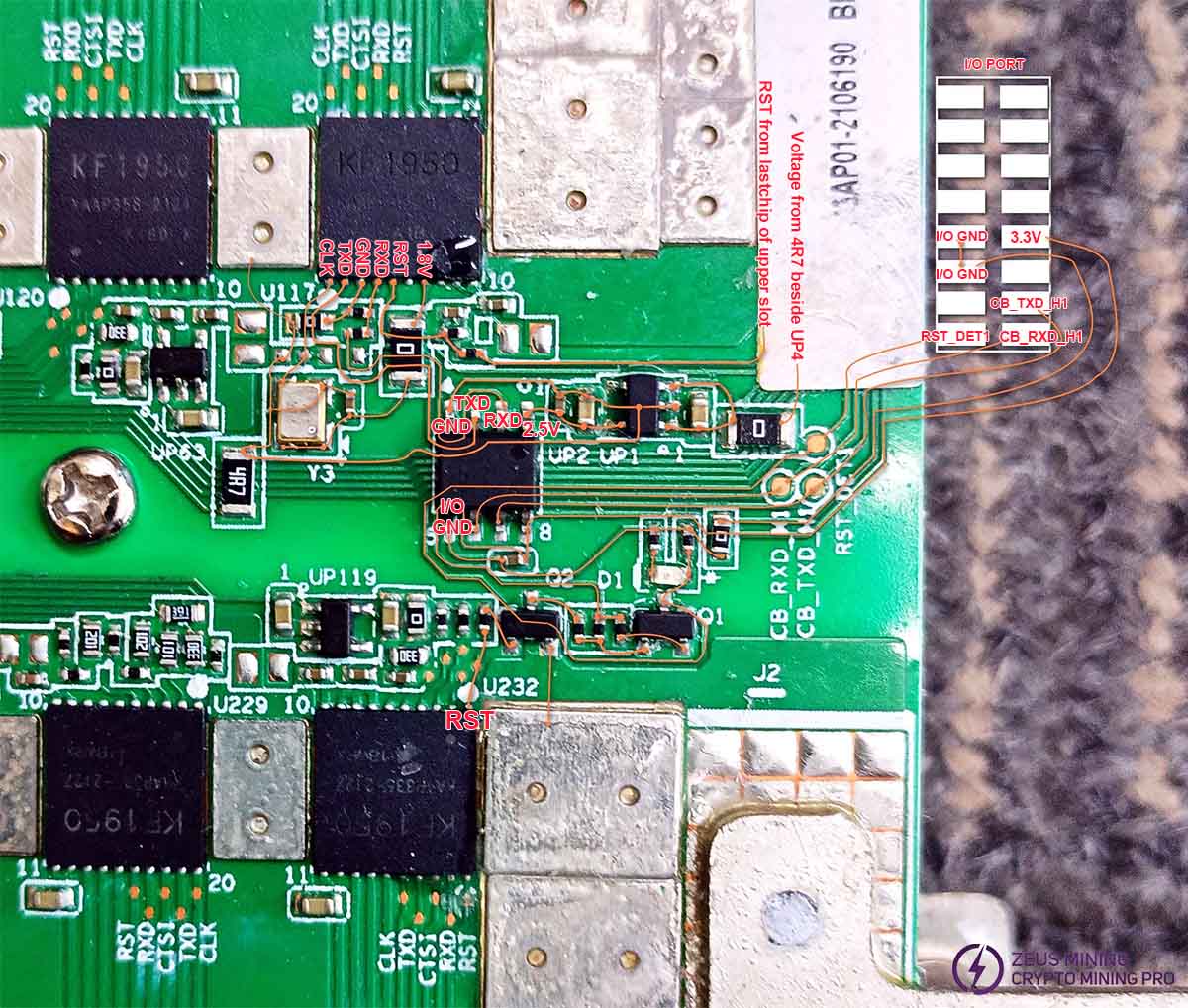

5. Connection diagram of the fixture control board

6. Test power supply

Hash board power supply: 42VDC, 15A

Fixture control board power supply: 12VDC, 2A

7. Tools and materials:

Heating platform, multimeter, oscilloscope, tweezers, solder paste, flux

II. Introduction to Circuit Principles

1. Overall machine structure

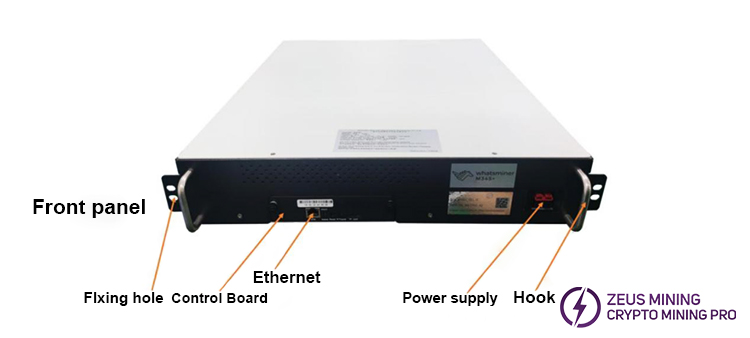

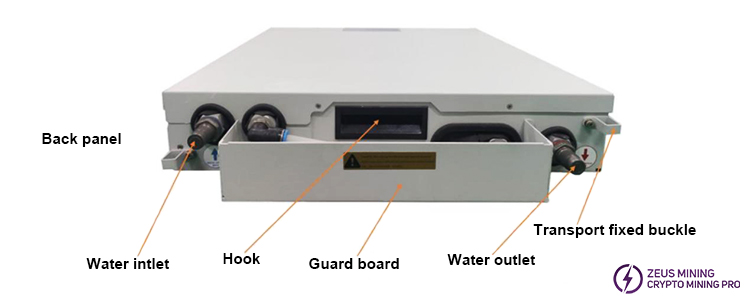

A machine consists of a three-phase power supply, a hash board, and a control board. Both the power supply and the hash board are equipped with water cooling radiators (as shown in the figure).

2. Water cooling hash board circuit description

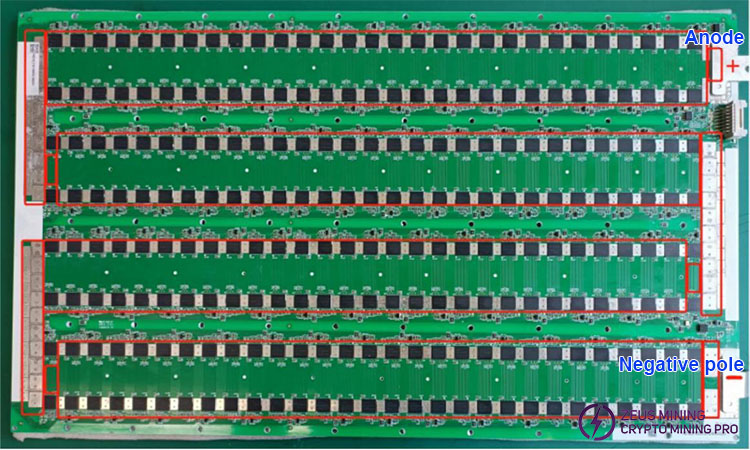

1) The circuit board is powered in series as shown in the diagram:

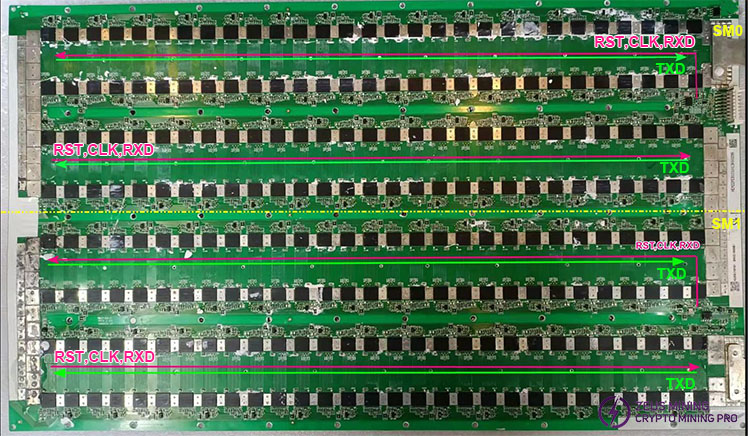

2) Signal circuit:

A hash board consists of SM0 and SM1. The SM0 signals RST, RXD, and CLK are transmitted from U1 to U116, while TXD is transmitted from U116 back to U1, and then returned to the control board via UP3.

For SM1, RST (from U116 of SM0), RXD (sent from the control board via UP2), and CLK are transmitted from U117 to U232, while TXD is transmitted from U232 back to U117, and then sent back to the control board via UP2.

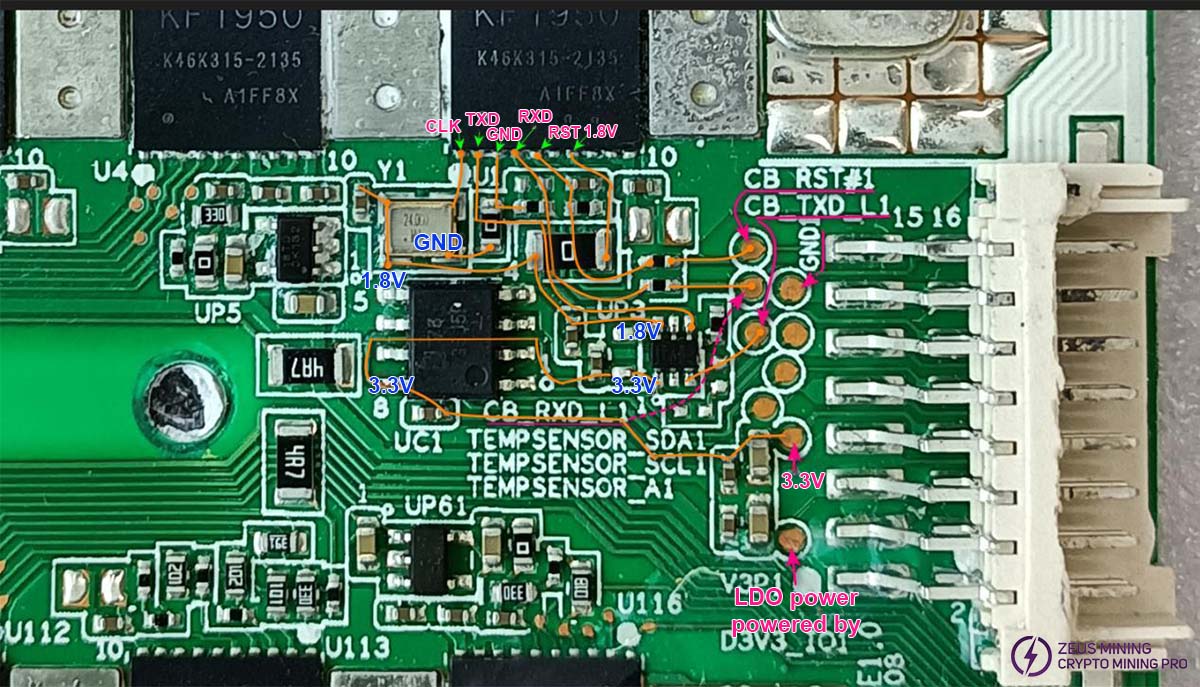

3) Wiring diagram of each signal for the SM0 port

The first eight LDOs of the SM0 are powered by the control board. Initially, they are in a low-voltage, no-input state. They only switch to a high-voltage state and receive input voltage after a POWER ON command is executed or during a hash board test.

4) SM1 port signal routing diagram

The RST signal for SM1 originates from the last chip, U117, of SM0. Both the RXD and TXD signals undergo level conversion through the UP2 chip before entering and exiting the control board via the I/O ports. On the entire board, only the RST signal runs across the entire board.

III. Safety Precautions

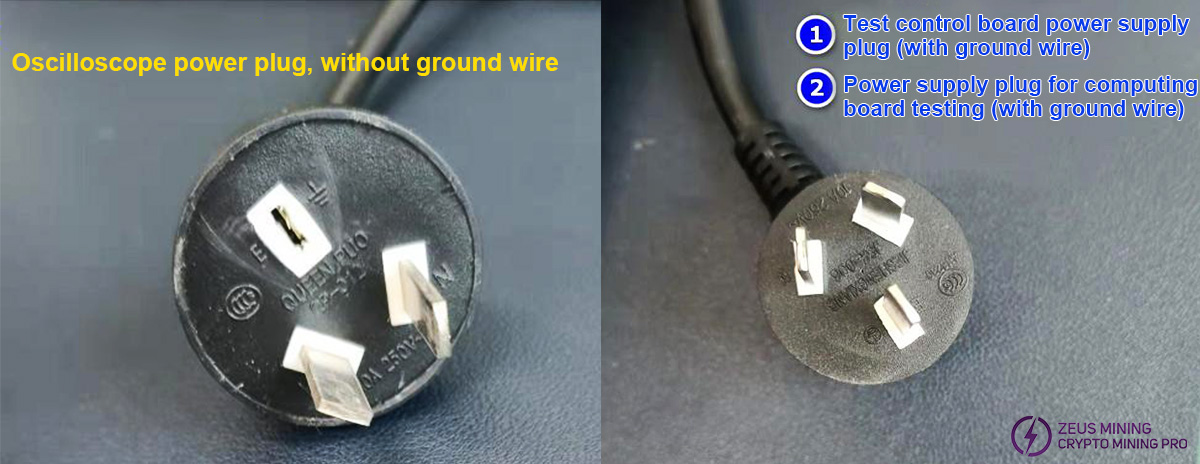

Since the power supply uses a 3-phase AC input, to ensure personal safety, the power supply for the test fixture control board and the power supply for the hash board must both use three-prong plugs (including a ground wire) and be reliably grounded. If using an oscilloscope to measure signals, the oscilloscope power cord plug must be a two-prong plug (without a ground wire); otherwise, the hash board will carry 110V AC power, posing a risk of electric shock.

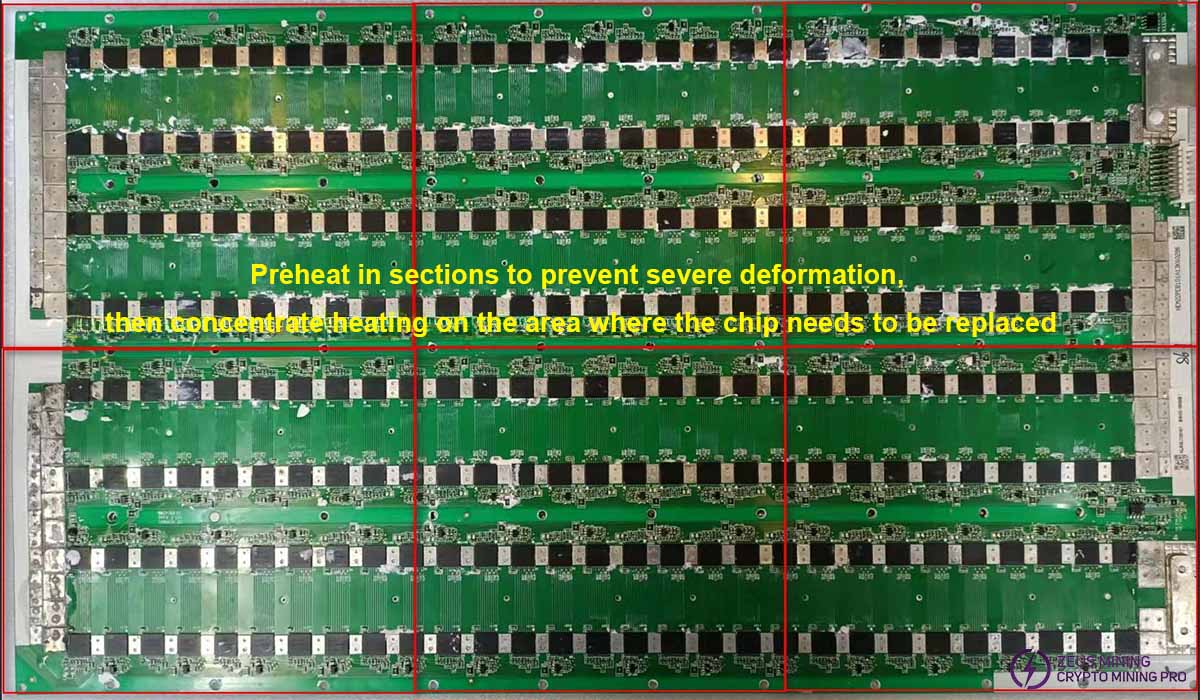

IV. Welding requirements

When soldering chips, the entire hash board must be preheated evenly before heating the specific area where the chip needs to be soldered. Without preheating, the large surface area of the hash board can cause deformation, leading to desoldering of chips in other areas, and in severe cases, even causing the solder pads to detach from the substrate, resulting in the board being unusable.

V. Assembly precautions

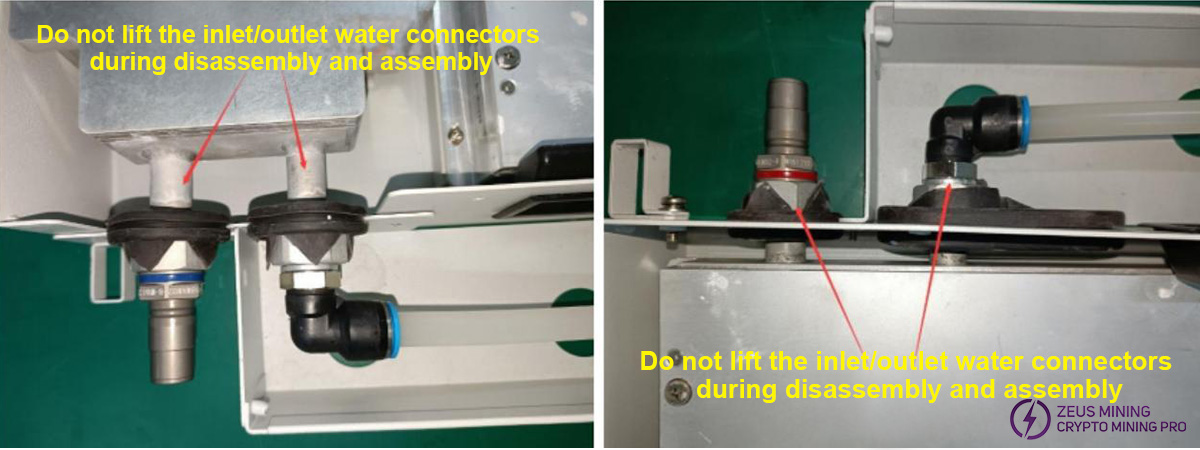

1) Do not lift the radiator inlet/outlet water connectors by hand during disassembly and assembly.

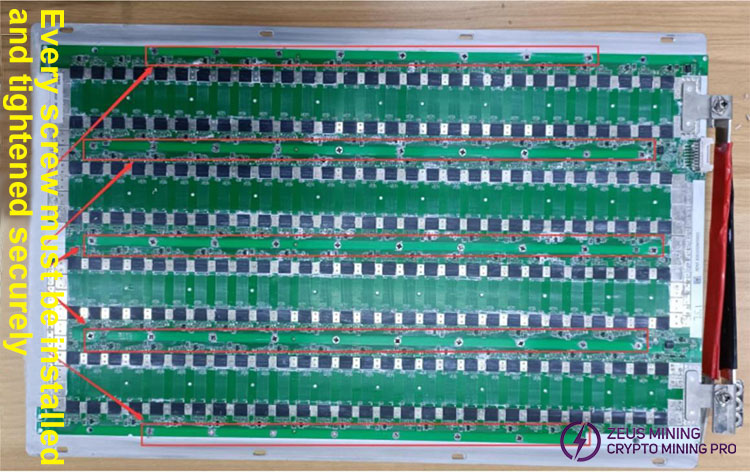

2) When installing the hash board onto the heatsink surface, ensure that all screws are tightened evenly and that none are missed, to prevent localized overheating.

VI. Troubleshooting and repair

Fault phenomenon | Reason | Troubleshooting methods |

The hash board is not detected | 1. No 3.3V 2. Cannot read EEPROM | 1. Check for short circuits in the 3.3V circuit. 2. Check if UC2 is functioning correctly. |

Unable to read the temperature sensor | 1. Faulty power supply 2. Defective chip | 1. Check the 3.3V power supply circuit. 2. Check if UC1 is working properly. |

Chip not read/incomplete | 1. Faulty RST signal 2. Faulty CLK signal 3. Faulty RXD signal 4. Faulty TXD signal 5. Faulty LDO power supply | 1. The interruption point of the RST signal is the fault location. 2. The interruption point of the CLK signal is the fault location. 3. The interruption point of the RXD signal is the fault location. 4. The interruption point of the TXD signal is the fault location. 5. The interruption point of the LDO signal is the fault location. |

Report high temperatures | 1. Chip temperature too high 2. uc1 reports high temperature | 1. Check if the screws and thermal paste are properly applied. 2. Check if the water temperature and flow rate meet the specifications. |

Low hash rate | 1. Poor power supply 2. A certain chip is returning fewer nonces | 1. Check the power supply output voltage; replace the power supply if the voltage is low. 2. Replace the chip that has a low nonce value. |

The remaining circuit principles and repair methods are basically the same as those of the air-cooled M30 series hash boards; please refer to the M3X series repair guide.

VII. Structural diagram

Dear Customers,

Hello everyone, as China is about to usher in the Spring Festival, international logistics will be suspended. Zeus Mining is scheduled to stop shipping on February 11, 2026, and start the Spring Festival holiday from February 12 to February 23, 2026 (GMT+8). Pre-sales and after-sales service will reply to the information on February 24, 2026, and shipping will resume on February 24, 2026. Thank you for your support and trust in 2025. In 2026 and the future, we will bring better products and services to our friends.

Best wishes,

ZEUS MINING CO., LTD.